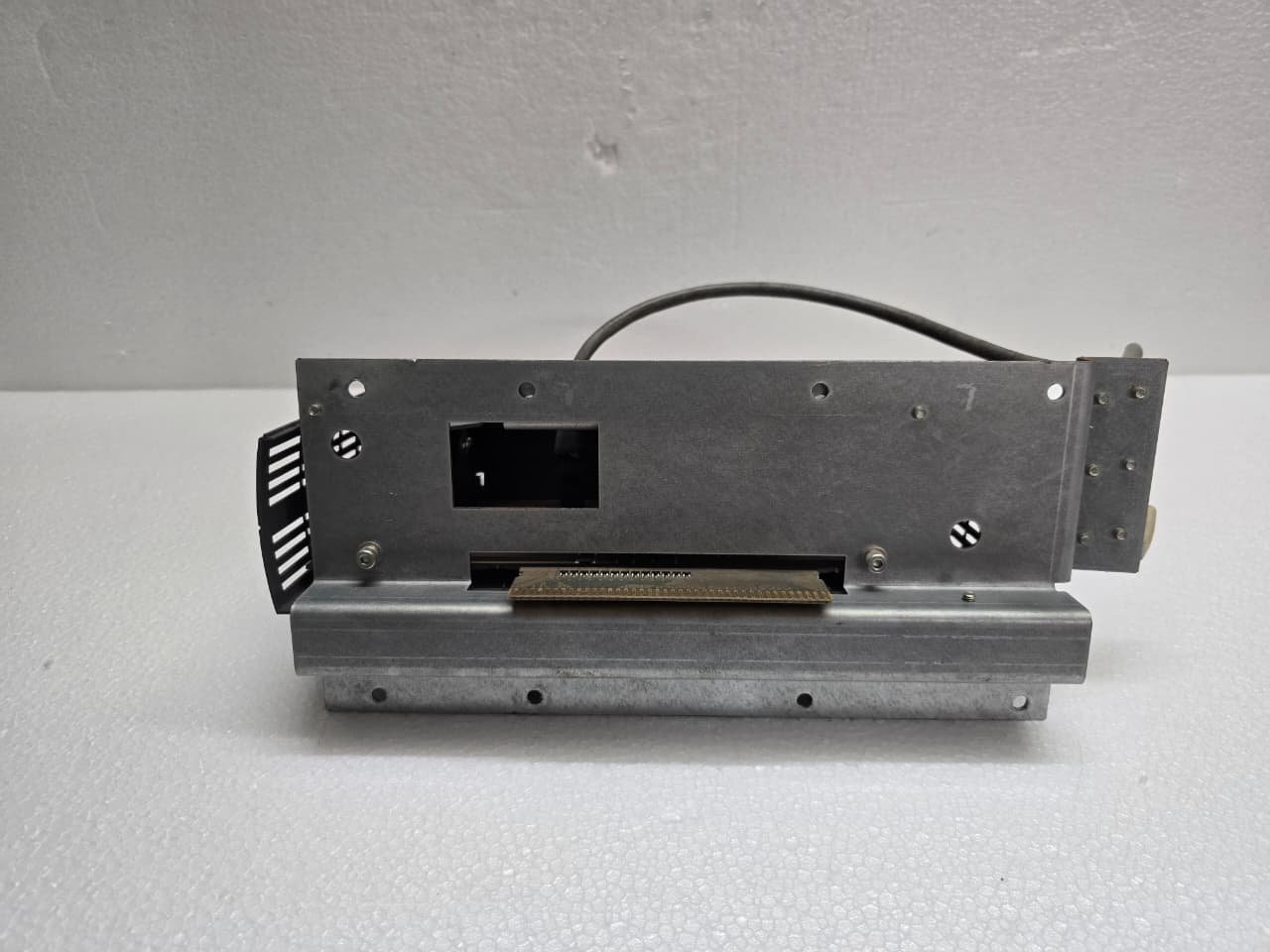

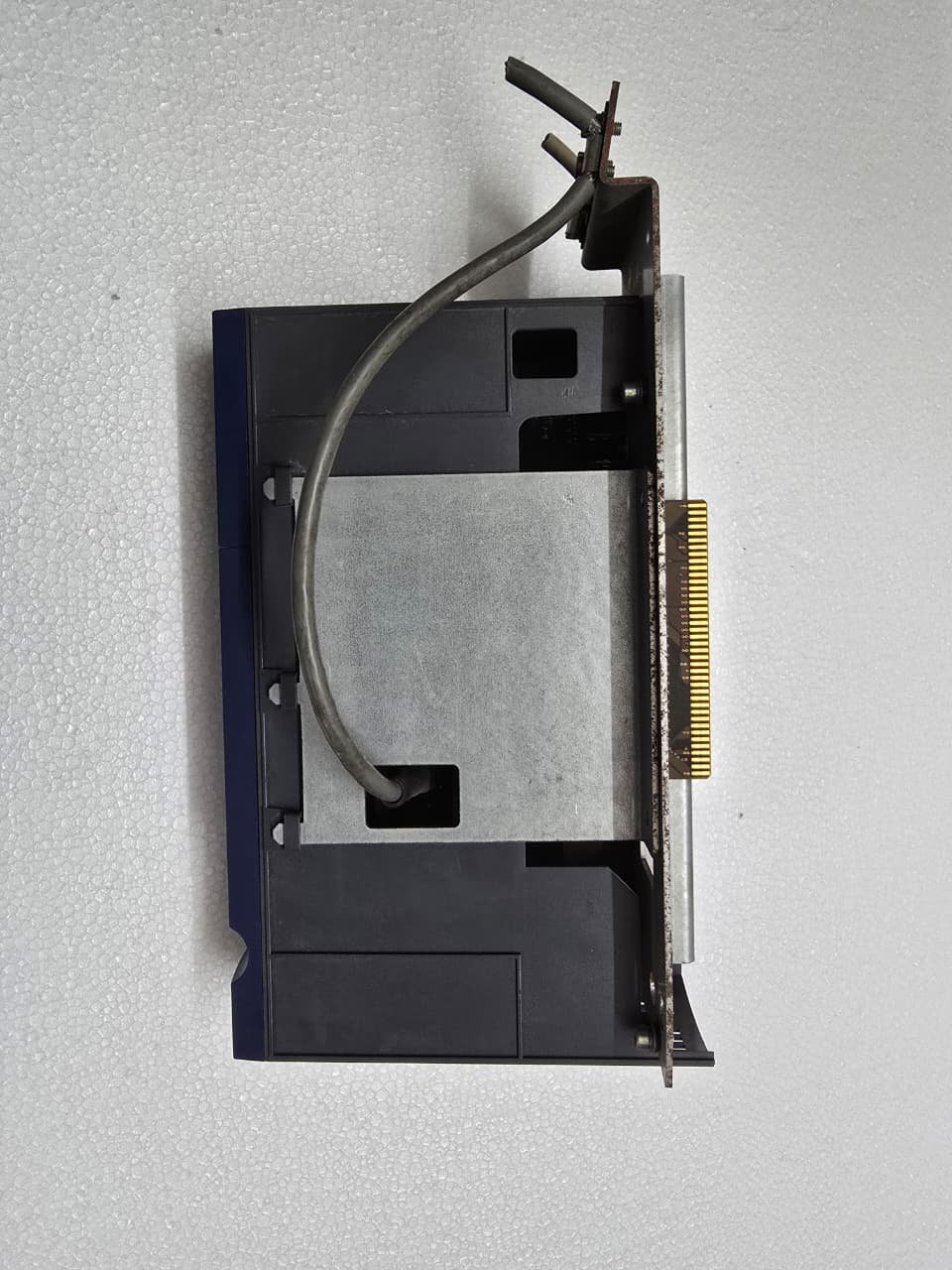

Bonfiglioli Vectron Active Power (AP) G402

$928.00 Original price was: $928.00.$624.00Current price is: $624.00.

The Bonfiglioli Vectron Active Power (AP) G402 is an industrial servo drive designed for high-precision control of synchronous servomotors and asynchronous motors. It is part of the Active Power series, which is known for its compact design and its ability to handle demanding motion control tasks like CNC machining, packaging, and robotics.

The G402 designation typically refers to a drive in the 400V class with a specific power rating (often around 4.0 kW / 9.0 Amps continuous, though this can vary based on the full catalog string).

Share:

The Bonfiglioli Vectron Active Power (AP) G402 is an industrial servo drive designed for high-precision control of synchronous servomotors and asynchronous motors. It is part of the Active Power series, which is known for its compact design and its ability to handle demanding motion control tasks like CNC machining, packaging, and robotics.

The G402 designation typically refers to a drive in the 400V class with a specific power rating (often around 4.0 kW / 9.0 Amps continuous, though this can vary based on the full catalog string).

1. Key Technical Specifications

The G402 is built for high dynamic response and sophisticated motion profiles.

| Feature | Details |

| Input Voltage | 3-Phase 360V to 480V AC |

| Output Current | Approx. 9.0 A (Continuous) / 18.0 A (Peak) |

| Control Modes | Position, Speed, and Torque Control |

| Feedback Support | Resolver, TTL Encoder, Sin/Cos, Hiperface, and EnDat |

| Braking | Integrated Chopper (Internal or External Resistor supported) |

2. Communication & System Integration

Bonfiglioli drives are highly modular. The “G402” base unit can be customized with various communication modules:

-

Fieldbus Options: CANopen (built-in on many models), EtherCAT, PROFINET, Profibus DP, and Modbus.

-

Expansion Slots: Features slots for additional I/O or specialized feedback cards (e.g., the EM-RES for resolver feedback or EM-ENC for encoder signals).

-

VABus: A proprietary internal bus for multi-axis synchronization.

3. Key Performance Features

-

Electronic Gearbox: Allows the drive to follow a master signal with a programmable ratio.

-

Cams (Electronic Camming): Supports complex non-linear motion profiles stored in the drive memory.

-

Safety Functions: Integrated Safe Torque Off (STO) to meet modern industrial safety standards (SIL 3 / PLe).

-

Oscilloscope Function: When used with the VPlus software, it provides a real-time trace of current, speed, and position for fine-tuning.

4. Wiring and Terminal Layout

-

Power Terminals (Bottom/Top): $L1, L2, L3$ for mains input and $U, V, W$ for motor output.

-

Control Terminals: Includes digital inputs (for Enable, Limit Switches) and relay outputs (for Brake control or Status).

-

DC Bus: Terminals for connecting an external braking resistor if the application involves high-inertia loads.

5. Common Fault Codes

The 7-segment display on the front (or the optional keypad) will flash error codes starting with “F”:

-

F0500: Overcurrent. Check for a short circuit in the motor cable or mechanical jam.

-

F0701: Overvoltage. Usually happens during fast deceleration. Check the braking resistor.

-

F1100: Over-temperature. Check the cooling fan and ensuring the heat sink isn’t clogged.

-

F1401: Feedback error. Check the encoder/resolver cable shielding and connections.

Reviews

There are no reviews yet.