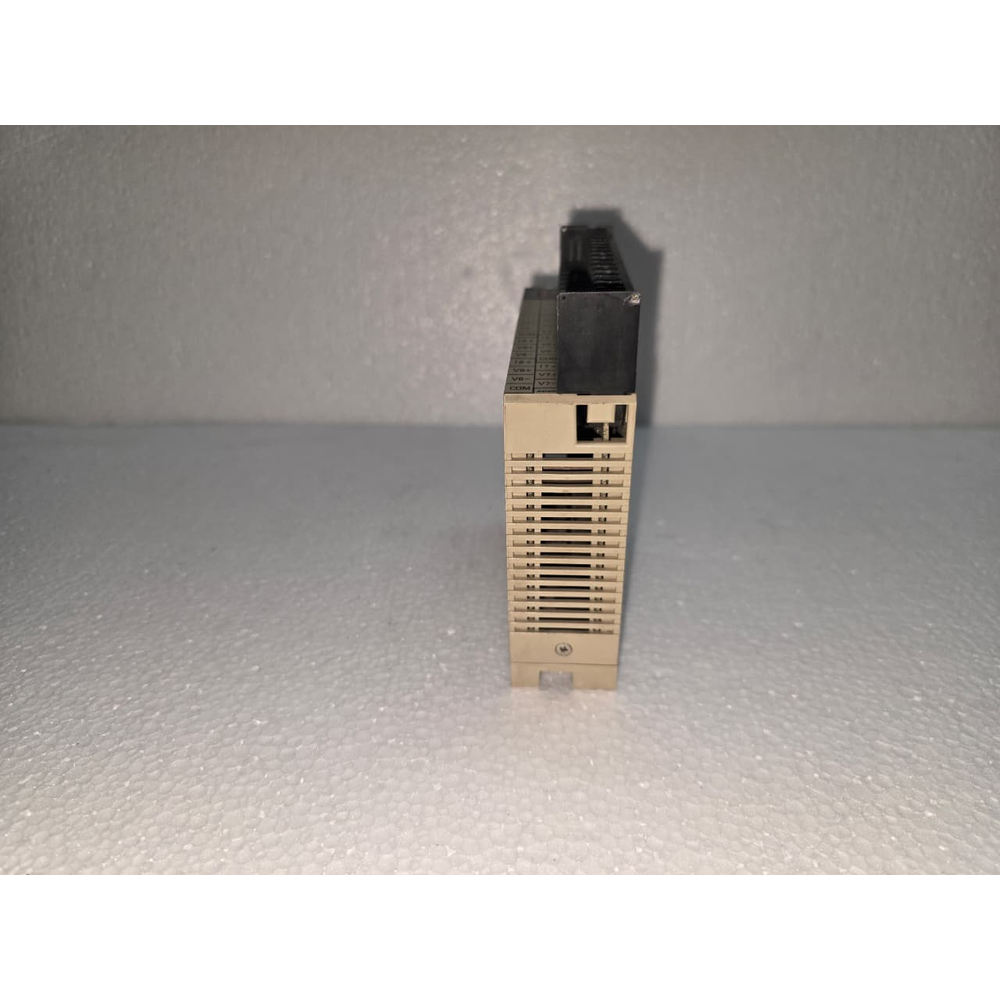

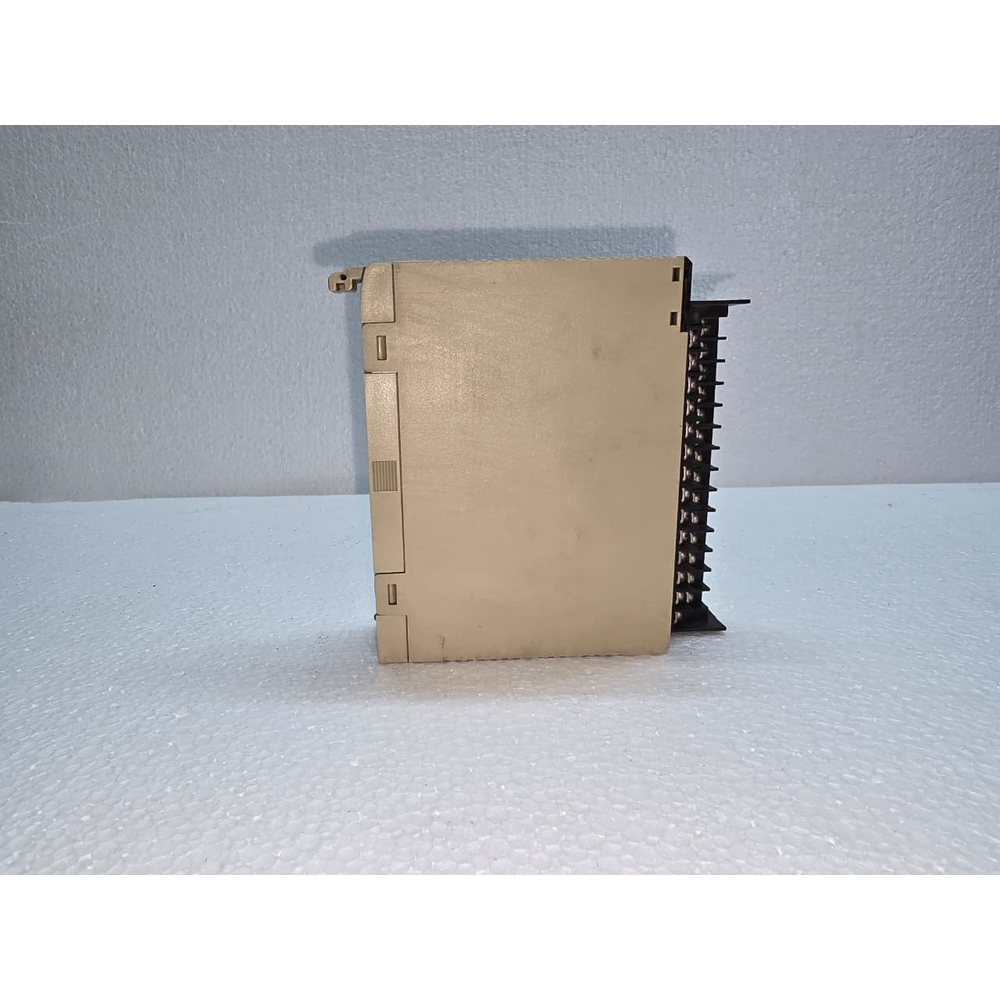

Omron C200H-AD003

$350.00 Original price was: $350.00.$210.00Current price is: $210.00.

the Omron C200H-AD003 is a high-performance Analog Input Module designed for the legendary C200H and C200H Alpha (α) series PLC systems.1 It is an “intelligent” I/O module that converts continuous analog signals from sensors (like pressure, temperature, or flow) into digital data that the PLC CPU can process.2

1. Channel Configuration

The AD003 is a high-density module compared to the basic AD001/002 models.

-

Input Channels: 8 Channels.3 This allows you to monitor up to 8 different analog sensors using a single slot on the PLC backplane.4

-

Signal Types: It is strictly a Voltage/Current input module. It does not support direct thermocouple or Pt100 connections (those require the TS-series modules).

2. Input Ranges and Resolution

The module is highly flexible; each channel can be configured independently for different signal ranges using internal DIP switches or software settings.5

-

Voltage Ranges:

-

$1\text{ to }5V$

-

$0\text{ to }5V$

-

$0\text{ to }10V$

-

$-10\text{ to }+10V$

-

-

Current Ranges:

-

$4\text{ to }20mA$

-

-

Resolution: 1/4000 (Full scale). This provides high precision for industrial measurements.

-

Conversion Speed: 1.0 ms per channel (8.0 ms total for all 8 channels).

3. Technical Specifications

| Feature | Details |

| Model | C200H-AD003 |

| I/O Points | 1024 points (Special I/O unit) |

| External Power | 24V DC $+10\% / -15\%$ (Required for the analog circuitry) |

| Current Consumption | 100mA max (at 5V DC) / 200mA max (at 24V DC) |

| Isolation | Photocoupler isolation between input terminals and PLC internal bus |

| Accuracy | $\pm 0.2\%$ to $\pm 0.4\%$ of full scale (depending on temperature) |

4. Wiring and Terminals

The module uses a removable terminal block, which allows you to replace a faulty module without disconnecting the field wiring.

-

Voltage Input: Connect the signal to the positive ($V+$) and negative ($COM$) terminals.

-

Current Input: To measure $4\text{–}20mA$, you must short the Voltage ($V+$) and Current ($I+$) terminals together for that specific channel.

5. Key Features

-

Mean Value Processing: The module can be programmed to take an average of several samples to “smooth out” electrical noise from the incoming signal.

-

Peak Hold: It can store the maximum value reached during a specific time period, useful for monitoring pressure spikes or maximum load.

-

Scaling: While basic scaling is usually done in the PLC ladder, the AD003 provides clean binary or BCD (Binary Coded Decimal) data for the CPU.

Maintenance & Troubleshooting

-

Run LED Off: If the “RUN” LED on the front of the module is not lit, check if the 24V DC external power supply is connected correctly to the top terminals.

-

Broken Wire Detection: When configured for $1\text{–}5V$ or $4\text{–}20mA$, the module can detect if a wire is disconnected and set a “disconnection” flag in the PLC memory.

-

Unit Number: Ensure the Machine Number rotary switch on the front is set to a unique value ($0\text{–}F$) that does not conflict with other Special I/O modules on the rack.

Share:

the Omron C200H-AD003 is a high-performance Analog Input Module designed for the legendary C200H and C200H Alpha (α) series PLC systems.1 It is an “intelligent” I/O module that converts continuous analog signals from sensors (like pressure, temperature, or flow) into digital data that the PLC CPU can process.2

1. Channel Configuration

The AD003 is a high-density module compared to the basic AD001/002 models.

-

Input Channels: 8 Channels.3 This allows you to monitor up to 8 different analog sensors using a single slot on the PLC backplane.4

-

Signal Types: It is strictly a Voltage/Current input module. It does not support direct thermocouple or Pt100 connections (those require the TS-series modules).

2. Input Ranges and Resolution

The module is highly flexible; each channel can be configured independently for different signal ranges using internal DIP switches or software settings.5

-

Voltage Ranges:

-

$1\text{ to }5V$

-

$0\text{ to }5V$

-

$0\text{ to }10V$

-

$-10\text{ to }+10V$

-

-

Current Ranges:

-

$4\text{ to }20mA$

-

-

Resolution: 1/4000 (Full scale). This provides high precision for industrial measurements.

-

Conversion Speed: 1.0 ms per channel (8.0 ms total for all 8 channels).

3. Technical Specifications

| Feature | Details |

| Model | C200H-AD003 |

| I/O Points | 1024 points (Special I/O unit) |

| External Power | 24V DC $+10\% / -15\%$ (Required for the analog circuitry) |

| Current Consumption | 100mA max (at 5V DC) / 200mA max (at 24V DC) |

| Isolation | Photocoupler isolation between input terminals and PLC internal bus |

| Accuracy | $\pm 0.2\%$ to $\pm 0.4\%$ of full scale (depending on temperature) |

4. Wiring and Terminals

The module uses a removable terminal block, which allows you to replace a faulty module without disconnecting the field wiring.

-

Voltage Input: Connect the signal to the positive ($V+$) and negative ($COM$) terminals.

-

Current Input: To measure $4\text{–}20mA$, you must short the Voltage ($V+$) and Current ($I+$) terminals together for that specific channel.

5. Key Features

-

Mean Value Processing: The module can be programmed to take an average of several samples to “smooth out” electrical noise from the incoming signal.

-

Peak Hold: It can store the maximum value reached during a specific time period, useful for monitoring pressure spikes or maximum load.

-

Scaling: While basic scaling is usually done in the PLC ladder, the AD003 provides clean binary or BCD (Binary Coded Decimal) data for the CPU.

Maintenance & Troubleshooting

-

Run LED Off: If the “RUN” LED on the front of the module is not lit, check if the 24V DC external power supply is connected correctly to the top terminals.

-

Broken Wire Detection: When configured for $1\text{–}5V$ or $4\text{–}20mA$, the module can detect if a wire is disconnected and set a “disconnection” flag in the PLC memory.

-

Unit Number: Ensure the Machine Number rotary switch on the front is set to a unique value ($0\text{–}F$) that does not conflict with other Special I/O modules on the rack.

Reviews

There are no reviews yet.